Margaret Knight was born in York, Maine, U.S.A., on February 14, 1838, to James and Hannah (Teal) Knight. Ms. Knight and her brothers Charlie and Jim were raised by her widowed mother in Manchester, New Hampshire. Always interested in building and inventing things, Ms. Knight turned her attention to the machines in the textiles mills. Before she was a teenager, her first invention was put to use in the mills.

Ms. Knight moved to Springfield, Massachusetts, and took a job at the Columbia Paper Bag Company following the Civil War. It was here that she invented a machine to fold and glue paper to form satchel-bottom, or flat-bottom, bags. She studied the machines at the factory during the day and made drawings and models at night in the boarding house where she lived. Margaret Knight’s bag machine was patented July 11, 1871, as patent #116,842. This was a difficult achievement, as Ms. Knight had to defend her work against Charles F. Annan, a man who had spied on the machinist hired to make her model and been granted a patent for an identical machine.

Margaret Knight was one of the first women to hold a patent. Before passing away in 1914, Knight acquired as many as 26 patents in diverse industries. She also co-founded Eastern Paper Bag Company in Hartford, Connecticut.

The invention greatly impacted the paper industry, as satchel-bottom bags became a choice material for carrying and transporting goods. The large New York department stores of Macy’s and Lord & Taylor’s realized how they could utilize the flat-bottom bags to accommodate customer needs without having to take time to wrap a parcel with paper and twine. It was reported in Anne. L. MacDonald’s book Feminine Ingenuity that Knight’s paper bag machine replaced the work of 30 people and “attracted extraordinary attention in Europe and America.”

Today, in excess of 7,000 machines throughout the world produce flat-bottom paper bags, now known as “stand-on-shelf” or “self-opening sacks” (S.O.S). Major suppliers of these machines are H.G. Weber & Co., headquartered in Kiel, Wisconsin, U.S.A., two firms in Germany, and one each in France and Japan.

Paper bag machines today are producing 200 to 650 sacks per minute. End uses of S.O.S. bags include grocery and department stores, fast food restaurants, and bakeries. S.O.S. bags are also found in lunch rooms; on store shelves for consumer products, coffee, pet food, and charcoal; and at home for composting and yard waste.

Ms. Knight passed away on October 12, 1914, in Framingham, Massachusetts. She never married.

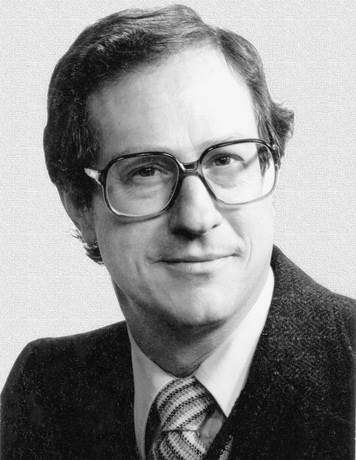

Illustration of Ms. Knight is from MARVELOUS MATTIE: HOW MARGARET E. KNIGHT BECAME AN INVENTOR by Emily Arnold McCully. Copyright (c) 2006 by Emily Arnold McCully. Reprinted or Used by permission of Farrar, Straus and Giroux, LLC.